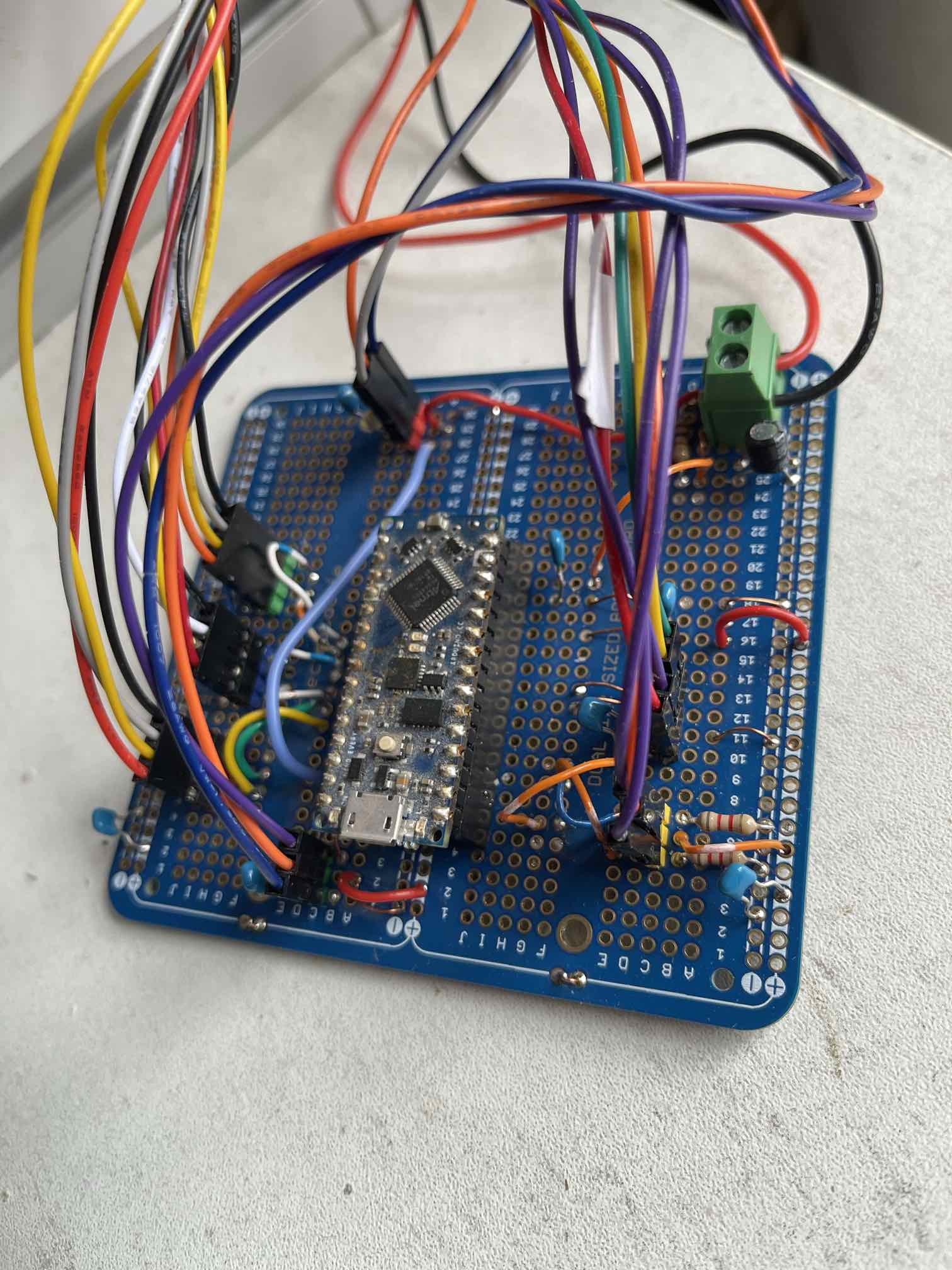

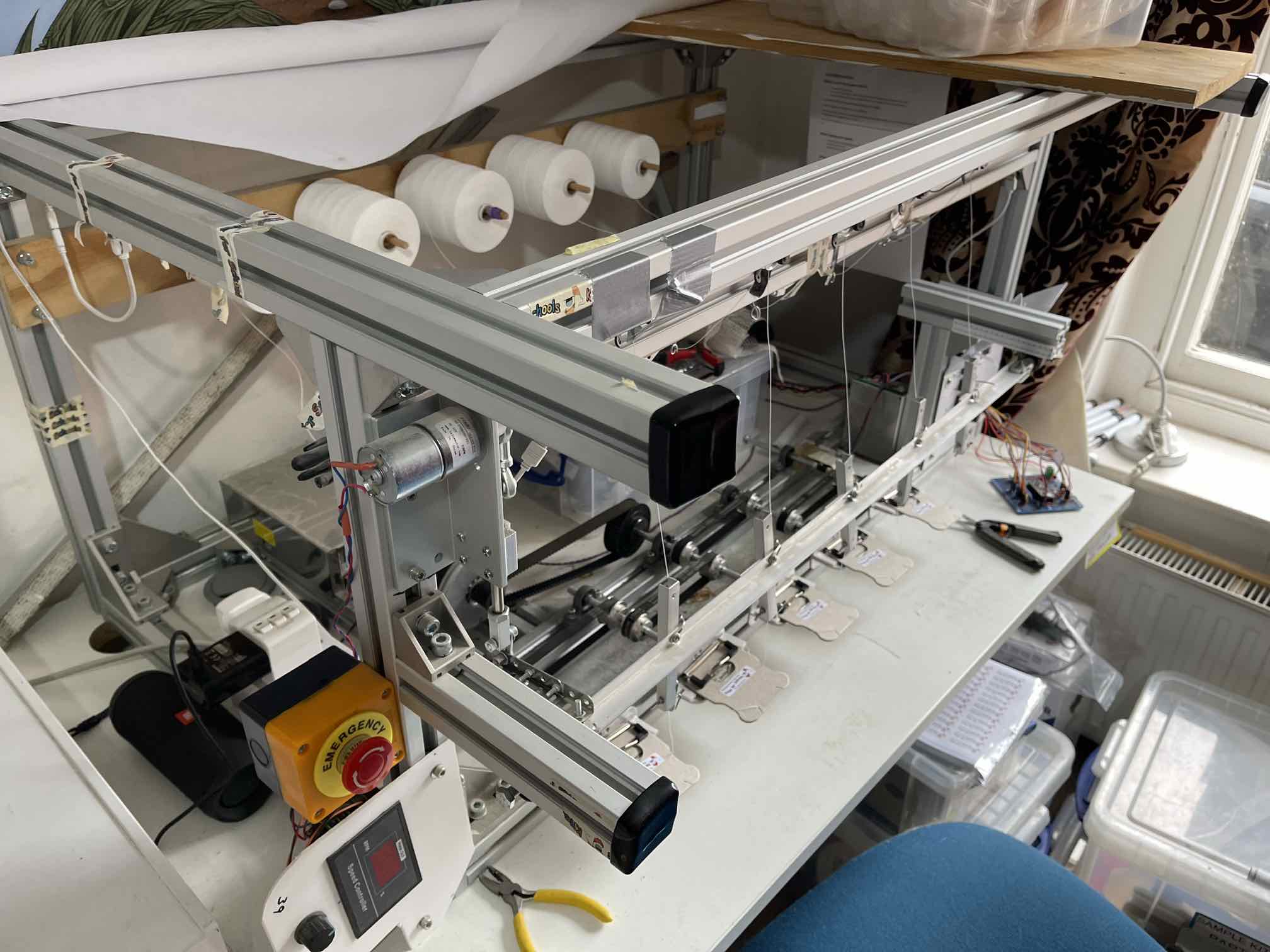

On a visit to my Dad he showed me his custom rig for winding kite handles at scale for craft kits – driven by Arduino. (Arduino Every). The connection to the display counter board is I2C wire protocol.

A potentiometer is used to control speed. This is on the power line to the motor – not connected digitally.

The logic board reads a button to start and stop the device. This is connected on the I/O pins to the arduino.

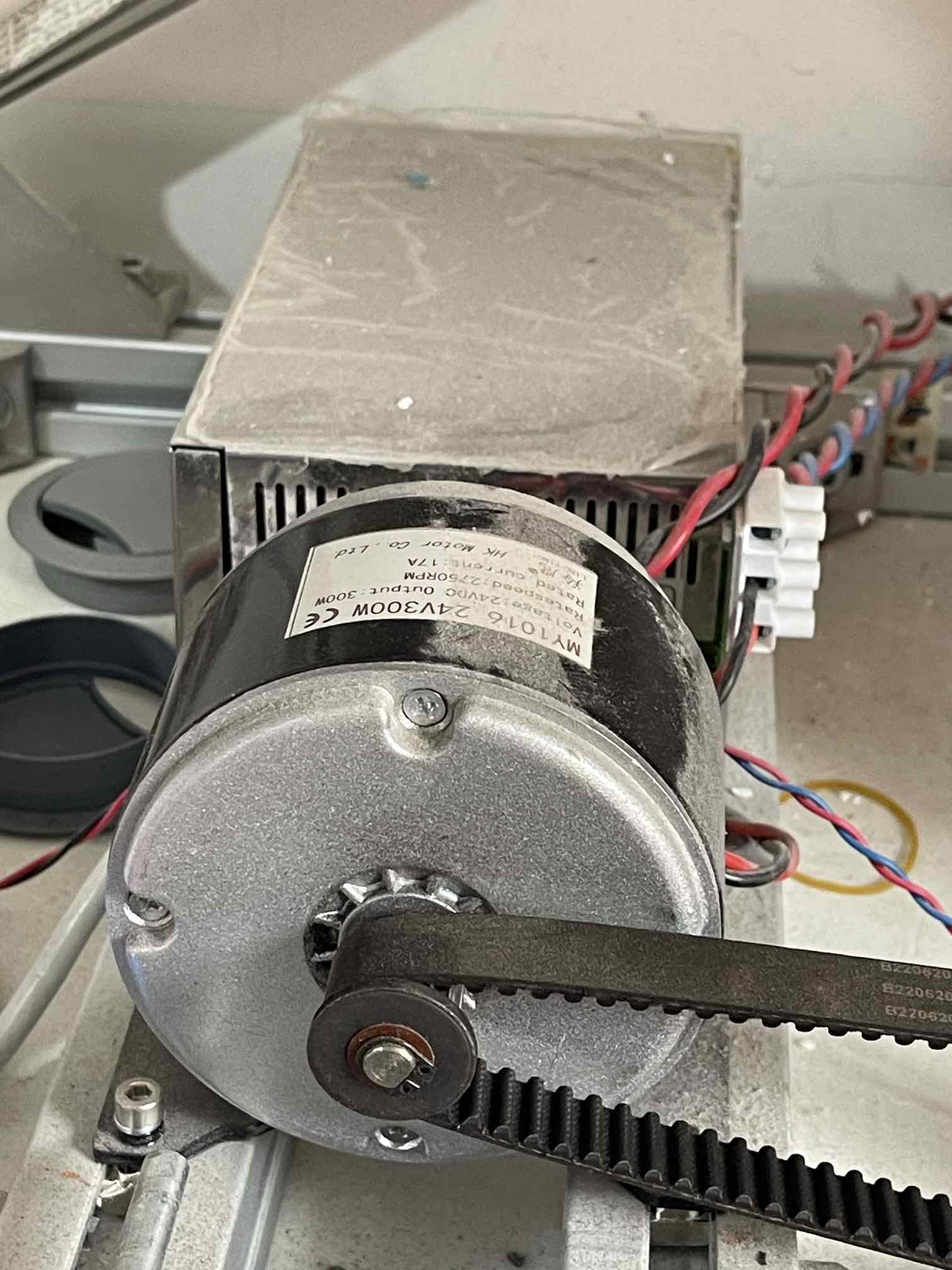

The arduino logic board triggers a scooter motor which drives the toothed belts connected to the axles.

The axles hold cardboard kite handles held in with pad folder clips.

There is a second mechanism to oscillate the string guides to spread the string evenly across the handle. This stops bunching and slipping of the string off the handle.

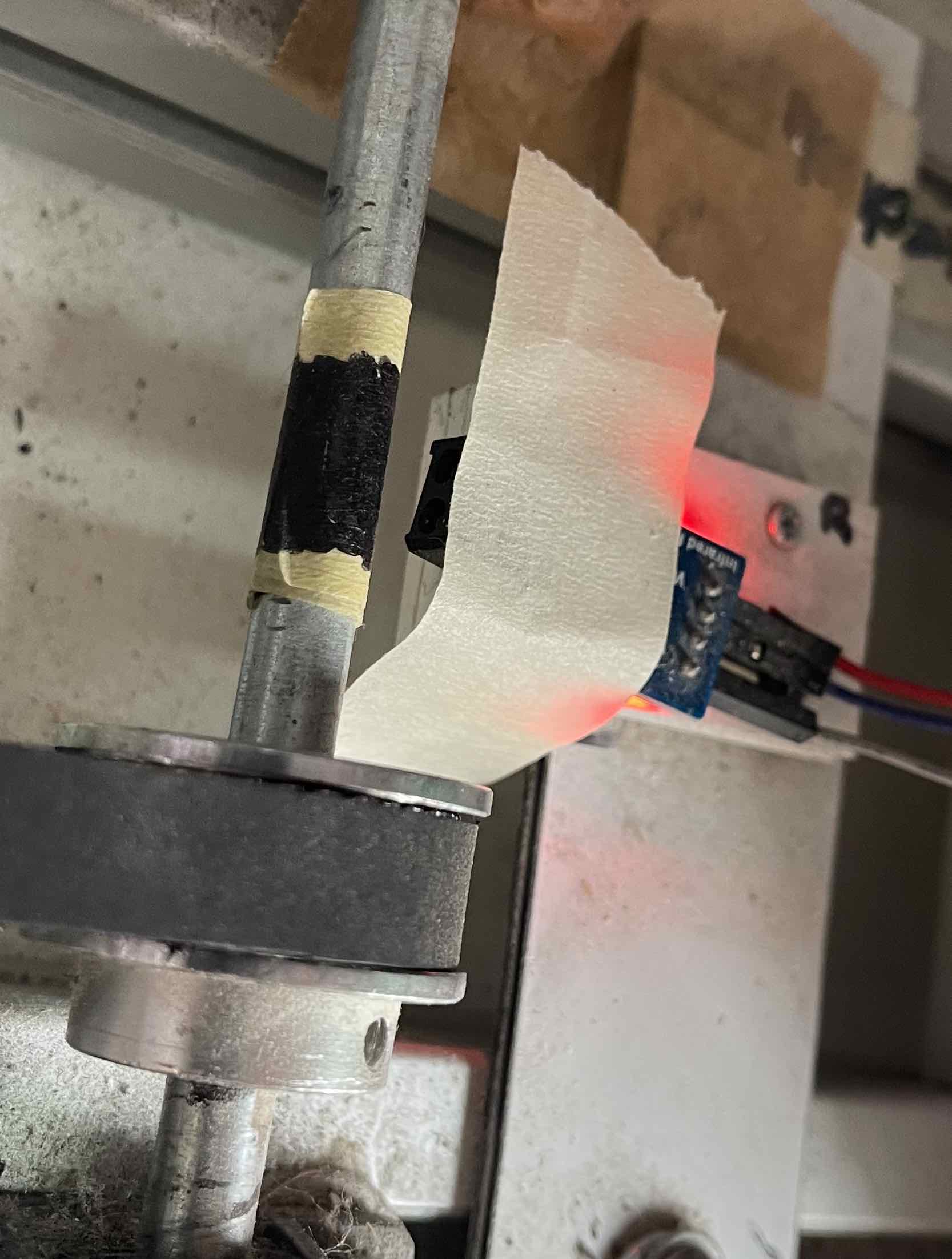

There is an axle tab with an optical detector board with source LED and detector that looks at the reflection off the shaft. The tab is covered with black from a texta.

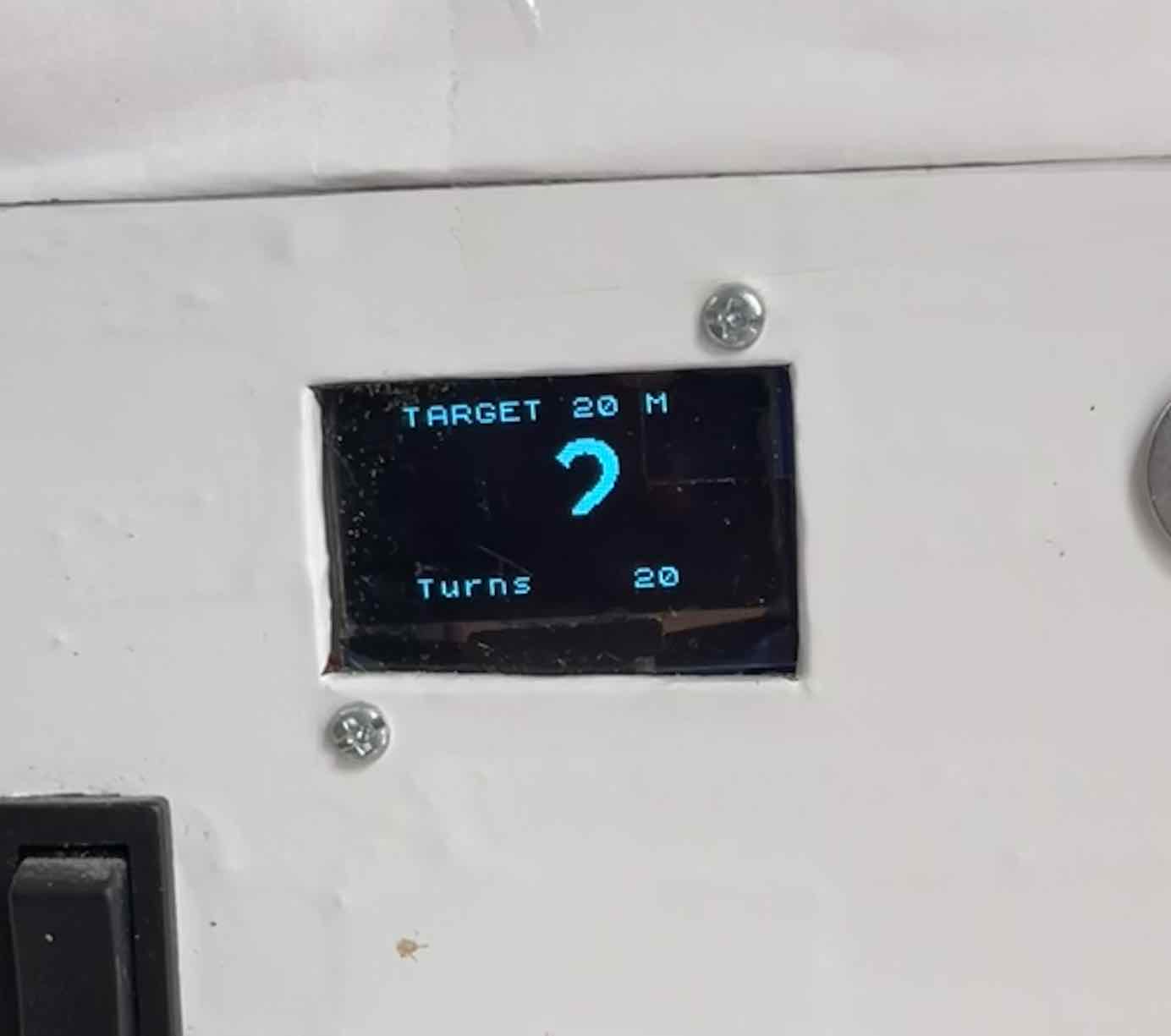

There is an input button for setting the desired number of meters.

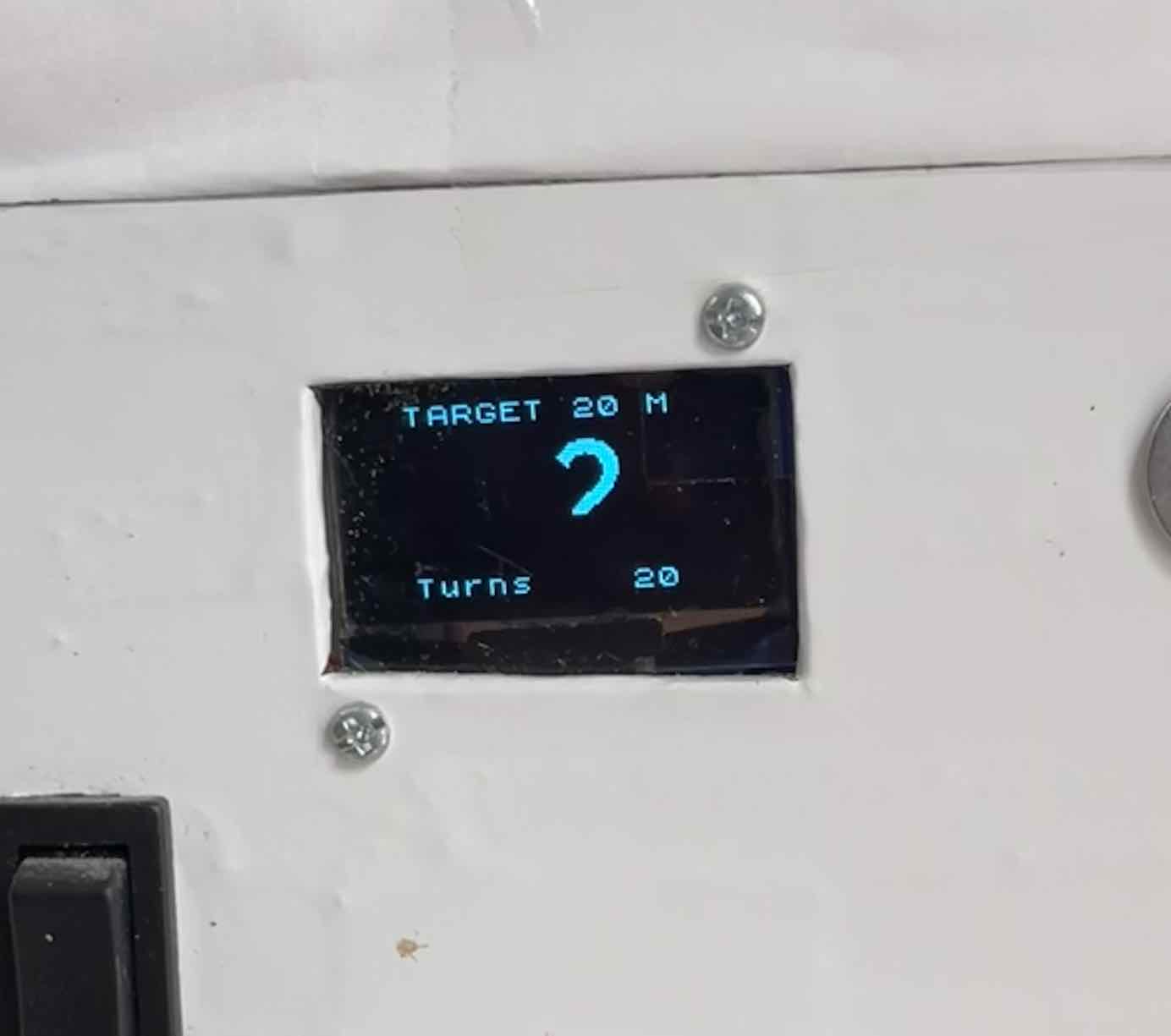

The Ardiuno system outputs the desired number of meters on the display.

After the start button is pressed, the Ardiuno system counts the number of rotations from the optical sensor, does a ratio calculation to meters wound, and stops after the desired number of metres.

The output display shows winding progress. (The strobing/refresh of the display has caught the larger meter count in mid-refresh.)

After completion the handle is removed from the clip and is nearly ready for shipping.

This is the overall System.

This is the system running.

Scale

This has the capacity to do about 120-130 handles per hour.

Engineering Iterations and Reflections:

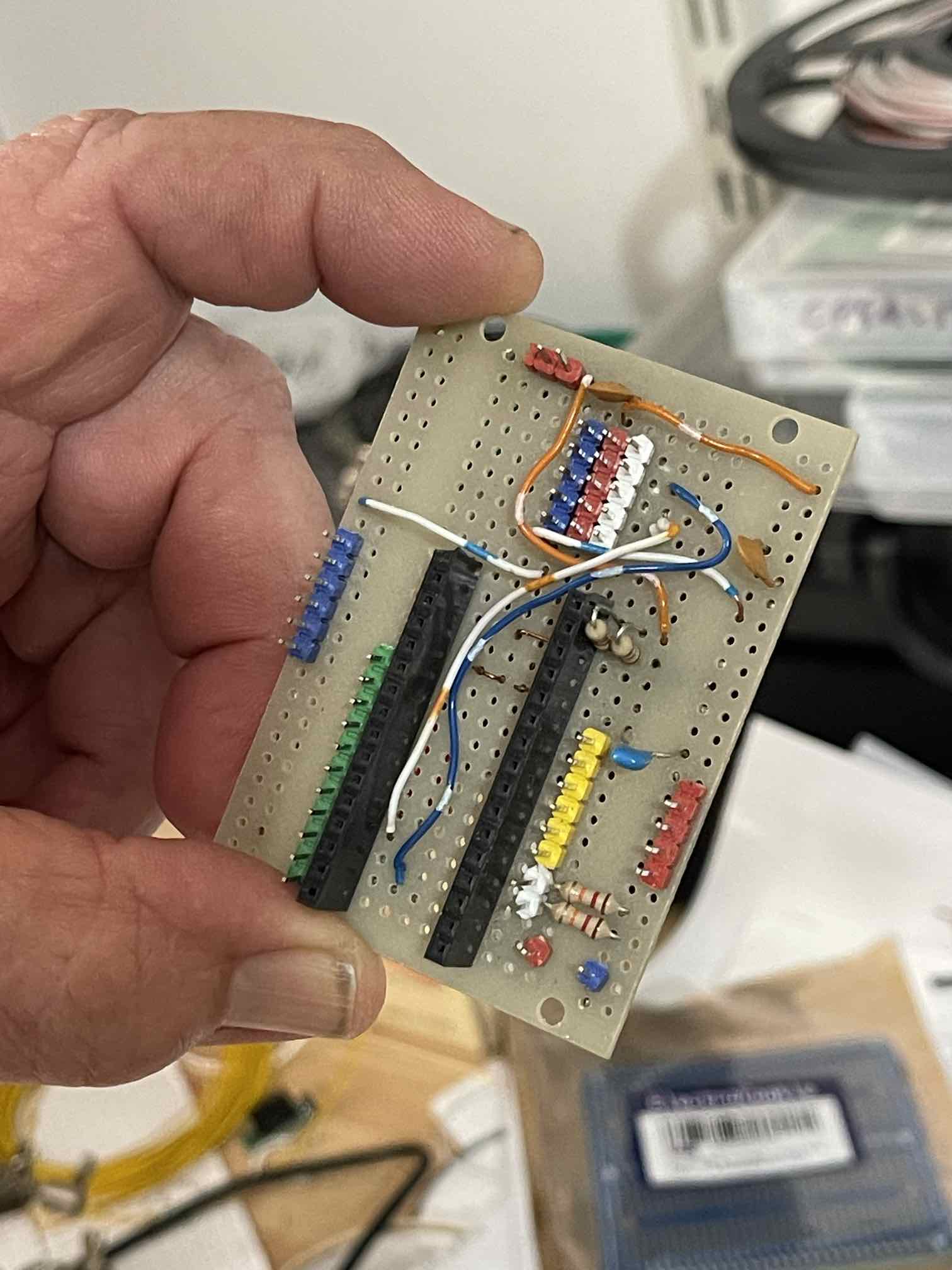

This logic board is the first attempt, different to the second board shown further above. On the first attempt, power glitches on the first attempt. The logic board at the top of the post has added capacitors to solve coupling problems.

One of the issues encountered on early software development iterations was that the system would miss the exact matching target length and keep going even if the target length had been exceeded.

This is Dad’s workshop. It is reminiscent of the place where he taught me to solder, and to reason about electrical systems.